A large number of vehicles and equipment like dumper trucks, trucks with tipping bodies and cranes are used in construction industry. The application for which these equipment are used, involves loading, unloading or transporting construction material. It is highly recommended to use a tilt sensor or a tilt switch on these vehicles or equipment for safe operation.

I. Why Cranes, Dumper Trucks And Other Construction Vehicles Need Tilt Switches?

When a dumper truck or tipping vehicle is unloading the construction material, due to the movement of the body of the vehicle, the center of gravity is constantly shifting. While some vehicles use simple tipping, few other applications require more complex forms of tipping such as three-way tipping. If during tipping, the safe angles are exceeded, the vehicle might topple down leading to serious damage to the vehicle, its hydraulic pack, people in the vicinity and the raw material being transferred. Incidents, where such accidents have resulted in the loss of life, are not uncommon and hence, from the driver safety point of view as well, these devices are must-haves. In the case of construction cranes also, if the crane arm exceeds the safe length or angles, the crane will be uprooted leading to a serious mishap.

Here Is a List Of All The Possible Mishaps That Might Happen During Operation Of These Vehicles:

- Exceeding Safe Angle: During tipping, a center of gravity of the vehicle constantly shifts. If the tipping is carried out beyond a certain safe angle, the vehicle might become unstable and topple.

- Overloading: If the vehicle body is loaded with more material than permissible, then the safe limits of operation will change and the vehicle will be prone to toppling even before the maximum safe limit is reached.

- Inclined Surfaces: When a vehicle is tipping on an inclined surface, it is prone to lose its stability faster.

- Moving While Tipping: If the vehicle is in motion during tipping, or brakes are suddenly applied to a moving vehicle while it is tipping, it might become unstable.

II. How Does a Tilt Sensor Or Switch Can Prevent Possible Mishap?

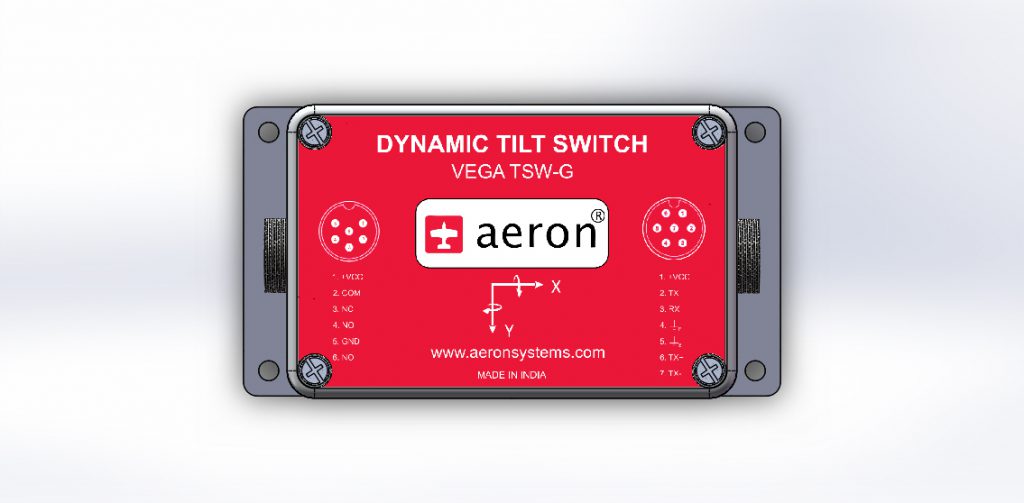

A Tilt Sensor or Tilt Switch is an inertial device (IMU) which monitors the angles in longitudinal and lateral directions of any platform to which it is attached. A tilt sensor consists of MEMS gyroscopes which calculate the change in the angle. A tilt switch is a nothing but a tilt sensor along with a relay which can give on or off signal to control operation of the platform. When the platform is oriented, the MEMS element in the device generates a signal proportional to the orientation. This signal is processed inside a microprocessor and the digital output of the angle is given out on serial interfaces. The Tilt Switch offers an option for configuration of safe operation angle limits – the relay is activated when the platform angle/booming angle reaches these safe operation angle limits. The relay connects with buzzer for operator attention and/or solenoid valve to stop the hydraulic operation altogether. In case of applications where the vehicles are tipping on a slanted platform, the device compensates for the tilt of the ground surface.

III. Why Tilt Switch Is Best Suited For The Safety Of Construction Vehicles?

- Compact: Tilt switch, as well as tilt sensors, are very compact and lightweight. This makes them highly suitable for installation on the vehicle or the crane.

- Surface Angle Compensation: These devices come with a provision to compensate for the angle of inclination of the surface on which they operate. On construction sites, where many times the vehicles unload on a highly uneven surface, this feature is highly useful.

- Ease Of Use: Tilt sensor and tilt switches are very easy to deploy and integrate with the vehicle in use.

- Provision For Buzzer Or Alarm: Tilt sensors and switches also come with a provision for ringing a buzzer/alarm when the safe angle limits are reached. This will alert the operator that he is about to breach the safety conditions

- Cost Effective: Tilt sensors and tilt switches are highly cost competitive and their prices are much smaller when compared with the quantum of losses that they prevent.

From the above article, it is quite clear that for the safety of boom cranes, dumper trucks and other tipping vehicles commonly used in the construction industry, tilt sensors and tilt switches are very useful. Progressive OEMs ensure that the vehicles manufactured by them have these devices on them. In case the device is not installed by the manufacturer, it can be easily purchased and installed on the vehicle.